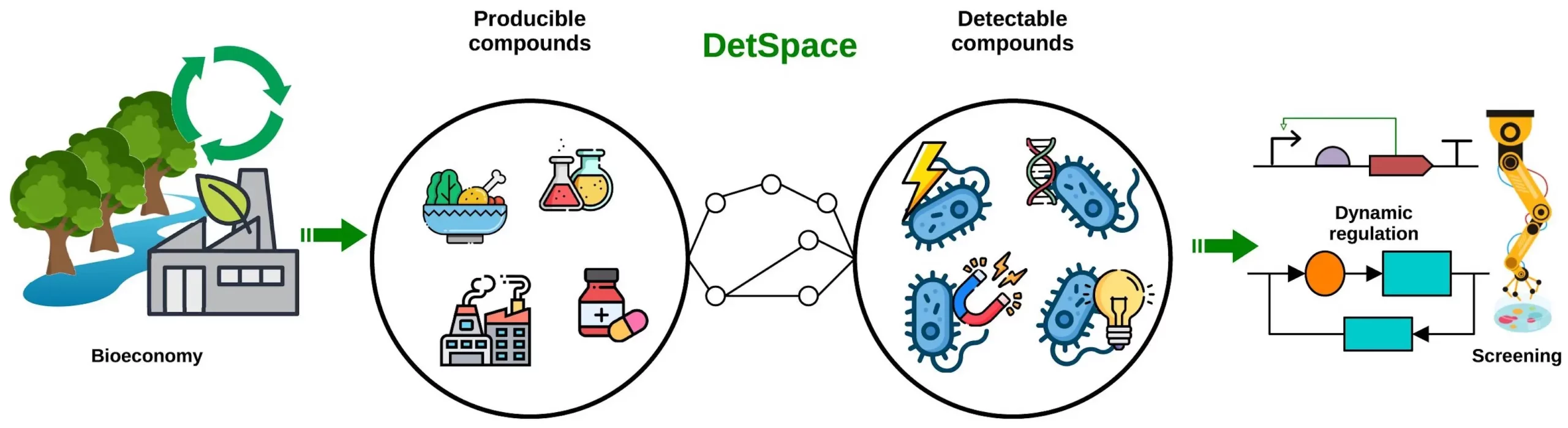

Think of a society where daily requirements – such as biofuels for cars and drugs to cure illnesses – are not manufactured in polluting production plants but made by living organisms with great care. This is not an idealistic dream but the very near future of biomanufacturing. Among the tools that will be instrumental in bringing about this thrilling change is DetSpace, an influential new web server.

But first, let’s talk about what led to the creation of DetSpace. Traditional chemical production depends on fossil fuels known to contribute significantly towards global warming. In contrast, biomanufacturing offers an environmentally friendly alternative; it employs microorganisms like bacteria and yeast to make necessary chemicals. Nevertheless, there are challenges to this method, especially when it comes to scaling up production efficiency in bioproduction facilities. Here’s where this software plays its role: as a conductor for these biological processes, optimizing them so that we can have sustainable materials for future use.

The Bottleneck: Tuning the Biomanufacturing

There are three main ingredients to successful biomanufacturing, namely titer, yield, and rate. The titer is the amount of concentration in which an expected product or musical masterpiece is being created; yield stands for how many products one gets out of starting materials, while rate refers to production speed- how quickly can this orchestra play symphonies? Efficiency in terms of these factors is critical to making commercial success achievable in biomanufacturing.

One way of achieving such efficiency involves dynamic pathway regulation. Think about a microscopic factory that changes its assembly line according to current demand. This is what dynamic regulation tries to accomplish – and DetSpace acts as an advanced instrument for designing finely tuned biomanufacturing pathways necessary for this approach.

DetSpace: Your Guide to Detectable Pathways

DetSpace functions as a user-friendly web server. This is achieved by generating detectable pathways, which are the steps involved in converting a target chemical into a detectable molecule. The latter serves as a signal for the biomanufacturing system to adjust production levels based on real-time requirements.

It can also be described as one of those feedback loops found in thermostats: when the temperature gets too high or low, heating or cooling systems are adjusted accordingly until things stabilize again. In this case, DetSpace has detectors that monitor the concentration of chemicals being produced along designed biomanufacturing pathways; they then regulate amounts made to maximize efficiency.

Under the Hood of DetSpace: A Look at the Maestro’s Toolkit

How does it work? Let’s take apart its different parts like instruments within a maestro’s toolkit:

- Discovering the Observable Kin: The DetSpace system has access to extensive databases that contain information on various chemicals, metabolic pathways, and their interactions in complex networks. Think of a giant library filled with blueprints for different molecular machines that make up life forms. The server looks for routes where the system converts your chemical into a detectable compound, just as a conductor finds appropriate instruments for playing a specific composition.

- The Predictive Power: Ingenious algorithms are employed by DetSpace to predict pathways. It uses bioretrosynthesis, which starts from the observable molecule and works backward until it identifies all necessary steps to reach your desired compound. This can be likened to a conductor studying an end score (detectable molecule) and then going back through individual musical lines (steps) required for achieving that piece.

- Efficiency Counts: Not only any but efficient pathways are provided by DetSpace. The server examines potential paths, taking into account factors such as the length of the steps involved (the length of the musical piece) and the availability of required enzymes (skilled musicians playing instruments). This way, you will get the most efficient route toward your target chemical, thus ensuring the smoothest possible biomanufacturing process outcome.

- From Design To Reality: Pathway selection alone doesn’t cut it; thus, DetSpace provides tools for translating designed pathways into practical biomanufacturing processes, connects you with resources for selecting suitable enzymes, and helps export pathway information in formats compatible with genetic engineering tools.

The Potential: Advantages of DetSpace

So, what are some possible uses for the DetSpace?

- Faster Growth of Bio-Based Products: This platform can speed up the creation of new bio-based products by optimizing the design of efficient biomanufacturing pathways.

- Lower Production Costs: Enhanced efficiency means reduced production expenses, hence making biomanufacturing more affordable than traditional chemical methods.

- Sustainable Manufacturing: Biomanufacturing is naturally sustainable. With DetSpace, it becomes possible to create greener ways of producing things while minimizing negative impacts on the environment.

- Wider Reach in Biomanufacturing: User-friendliness and robustness make this tool usable by anyone interested. Thus, many researchers and industries may access biomanufacture through DetSpace.

DetSpace Beyond Basic: Advanced Features

DetSpace offers more than basic pathway design capabilities:

- API Access: Researchers can use the Application Programming Interface (API) of DetSpace to programmatically access its features. This allows for integration with other software tools and the automation of biomanufacturing workflows.

- Customization Options: DetSpace lets users specify additional constraints, such as preferred chassis organisms or specific enzymes with desired properties. Such customization empowers researchers to tailor the design process according to their requirements.

- Community Features: In future versions, it is hoped that users will be able to share and work on biomanufacturing pathways together through DetSpace. This will create a collaborative atmosphere that fosters innovation within the field of biomanufacturing.

The Future is Bio-Based: A Call to Action

A significant advance in biomanufacturing technology, DetSpace represents self-guided evolution. The platform is designed for user convenience, with numerous tools that can be used by anyone, scientist or engineer alike, to develop efficient, sustainable processes involved in manufacturing using live organisms. In times like these, when we are working towards a better environment through our industries, it’s important not only for those who work directly with it but also for those indirectly involved, such as suppliers or customers, who should understand how their choices affect nature around them.

The DetSpace is free and open to all users; there is no login requirement, and it is available on the website.

Article Source: Reference Paper | The code is freely available on GitHub.

Follow Us!

Learn More:

Anchal is a consulting scientific writing intern at CBIRT with a passion for bioinformatics and its miracles. She is pursuing an MTech in Bioinformatics from Delhi Technological University, Delhi. Through engaging prose, she invites readers to explore the captivating world of bioinformatics, showcasing its groundbreaking contributions to understanding the mysteries of life. Besides science, she enjoys reading and painting.

[…] Transforming Bio-Chemical Engineering with DetSpace’s Detectable Pathway Design […]